Compounding Extruders

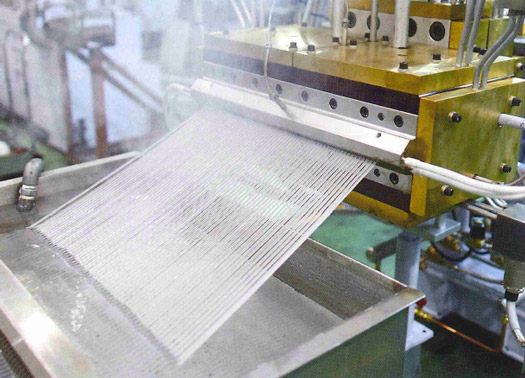

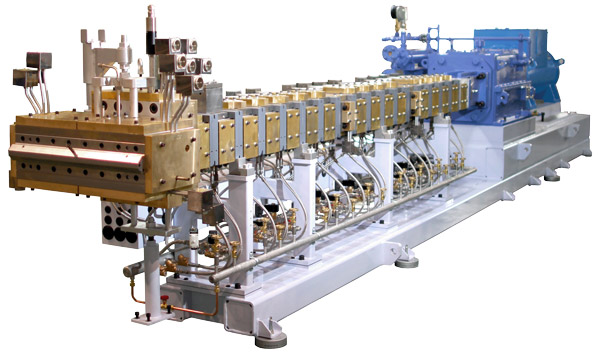

For compounding and reactive process, JSW stand ready to offer “TEX-αⅢ” series, which is our newest our twin screw extruder.

TEX-αⅢ has the world’s highest level torque (Td = 18.2 Nm/cm3) with deeper Do/Di ratio (1.57).

The highest torque of TEX-αⅢ makes it possible to operate the extruder with lower screw speed comparing with the existing extruder.

As a result, TEX-αⅢ can realize the lower energy consumption and lower discharge temperature.

TEX-αⅢ is also possible to design stronger mixing screw to increase throughput and improve mixing performance with its strong structure achieving highest level torque.

TEX-αⅢ has 9 line-up from TEX25αⅢ(screw dia. 26.5 mm) to TEX120αⅢ (129.5 mm).

Based on our great deal of experience for compounding and reactive process with original technology such as special mixing screw element (TKD, BMS) & barrel (NIC) and side feeder with degassing function (SFD), we can offer TEX-αⅢ to your needs from general compounding to high-end compounding.

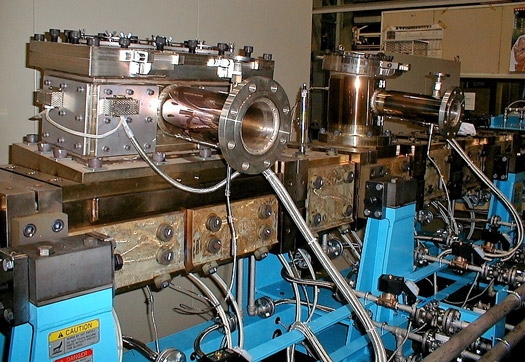

Devolatilization Extruders

For the isolation process after polymerization, we provide devolatilization extruder which has multi vacuum vent ports in order to remove residual solvent and/or monomer in the material polymers.

The maximum solvent and/or monomer concentration in our experience is 80% and our extruder can be applied to not only thermoplastics but also applied to synthetic rubber after solution polymerization and bulk polymerization.

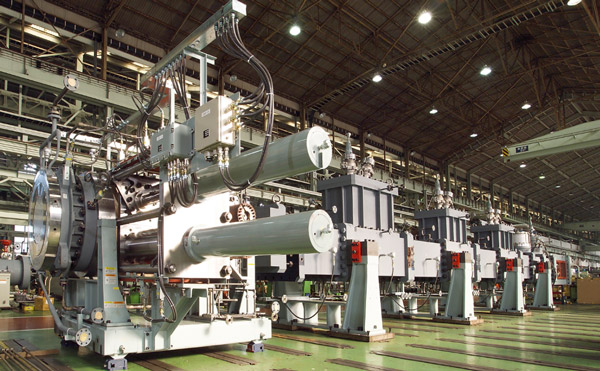

JSW has a lot of knowledge for devolatilization technology and delivery experiences. The our maximum sized TEX for devolatilization process is TEX400α for rubber and elastomer production, and it has 443 mm screw diameter, approx. 17 m screw length and total length of whole equipment is approx. 35 m.

JSW has resolved many difficult challenges of customers around the world by innovation and technology. This world’s largest devolatilization extruder is one example developed through JSW’s spirit of innovation.

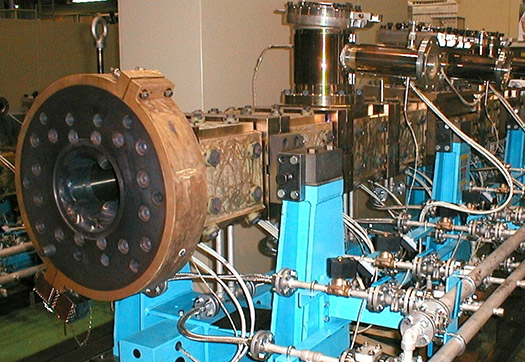

Dewatering Extruders

JSW provides the mechanical dewatering twin screw extruder for plastics, rubber and elastomer.

This dewatering technology can be applied to the solution polymerization, the emulsion polymerization and the suspension polymerization.

The rubber crumb after steam stripping process or coagulation process is fed into TEX then the rubber crumb is squeezed by screw of extruder, and then residual moisture in rubber is removed by vacuum drying or expansion drying.

The plastics after the suspension polymerization is also dewatered in the similar process.

In generally water content of feed material is around 90%.

The pre-dewatering equipment to reduce water content in rubber or plastics is required when TEX is applied.

On the other hand, our special single screw rubber dryer R-DE series, which has both squeezing and expanding functions can be applied to rubber and elastomer which contains 90% water.

The development of new dewatering technology such as TEX expansion drying system and special rubber dryer R-DE series is the result of our challenge with customer.